Table of Contents

Toggle- What Is Caustic Leaching

- Principle and Chemical Mechanism

- Application in Investment Casting Shell and Core Removal

- Comparison with Acid Leaching or Mechanical Removal

- Key Advantages of Caustic Leaching

- Waterson’s Process Integration and Quality Assurance

- Why Choose Waterson Investment Casting?

- Why Waterson Investment Casting Methods Stand Out

- Waterson Stainless Steel Investment Casting Solutions

What Is Caustic Leaching

Caustic leaching is a chemical process that uses concentrated sodium hydroxide (NaOH) solution to dissolve and remove silica-based residues from metal surfaces.

In investment casting, sometimes it’s difficult to remove the remaining ceramic material completely by mechanical removal method. The caustic leaching plays a crucial role during the shell removal or desilication stage — where remaining ceramic material must be removed without damaging the cast metal.

Compared to conventional acid cleaning, caustic leaching provides a safer and more environmentally responsible solution. It avoids corrosion on stainless-steel alloys such as SS304, SS316, and SS316L, ensuring smoother, contamination-free surfaces for post-machining or polishing.

Explore more about How Investment Casting Works to Deliver Excellent Metal Solutions

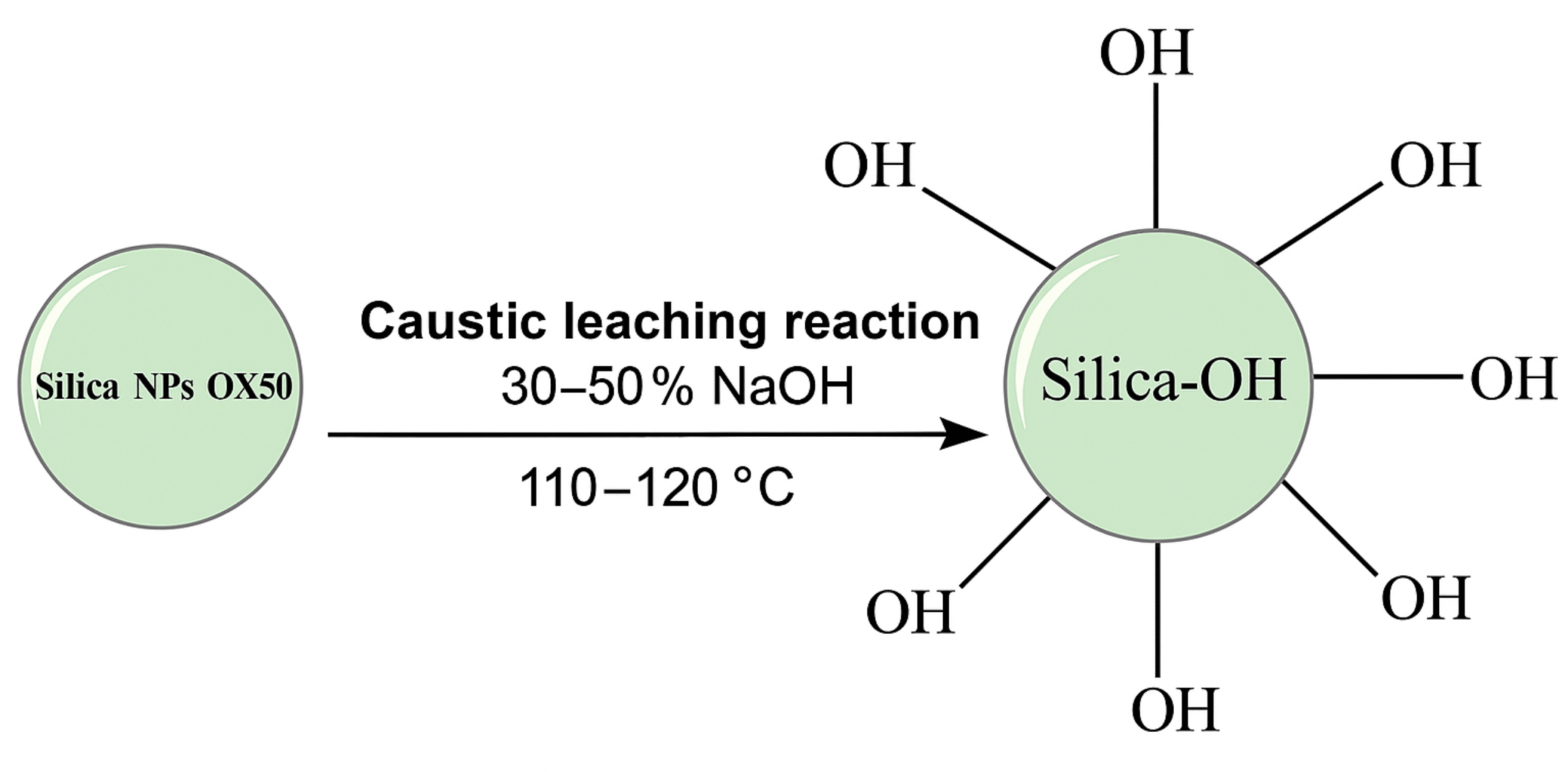

Principle and Chemical Mechanism

The main chemical reaction can be represented as:

SiO2+2NaOH→Na2SiO3+H2O

Caustic leaching works by dissolving silica (SiO₂) through its reaction with sodium hydroxide (NaOH), forming soluble sodium silicate that can be easily rinsed away.

In practice, the reaction efficiency depends on factors such as silica type, temperature, and alkali concentration. Maintaining proper conditions — typically 30–50% NaOH at 110–120 °C — ensures effective silica removal while preventing metal surface damage.

Application in Investment Casting Shell and Core Removal

In precision investment casting, caustic leaching is widely used after mechanical shell knockout to eliminate remaining silica or zircon particles, especially from narrow cavities or internal channels.

This process is particularly important for core removal and shell residue cleaning, ensuring the cast part is completely free from entrapped ceramic debris.

Caustic leaching is an established technique in removing ceramic cores from cooling channels and complex internal geometries.

Through a controlled caustic leaching bath, it achieves:

- Complete removal of silica-based shell or core residues

- Elimination of inclusions or embedded ceramic particles

- Enhanced surface preparation for polishing or passivation

Comparison with Acid Leaching or Mechanical Removal

| Method | Main Reagent | Effectiveness | Corrosion Risk | Environmental Impact |

| Caustic Leaching | NaOH (alkaline) | Excellent on silica | Low (under control) | Reduces acid waste |

| Acid Leaching | HCl / HNO₃ / HF | Effective on oxides | High | Generates hazardous waste |

| Mechanical Removal | Sandblast / Shotblast | Limited in cavities | None | Neutral |

Caustic leaching, when well-controlled, removes silica-based residues more thoroughly than mechanical cleaning and with less environmental impact than acid processes.

Key Advantages of Caustic Leaching

- Surface integrity: Avoids acid-induced corrosion and pitting.

- Eco-friendlier: Reduces acid waste and neutralization requirements.

- Efficiency: Eliminates manual rework and improves throughput.

- Consistency: Uniform desilication even in complex geometries.

Waterson’s Process Integration and Quality Assurance

At Waterson Corporation, caustic leaching is an integrated part of our post-casting cleaning workflow. In 2023, Waterson Corporation installed a newly designed enclosed caustic degreasing and leaching system, which received formal recognition from Taiwan’s Occupational Safety and Health Administration (OSHA), Ministry of Labor.

This upgraded system enables Waterson to further optimize the caustic leaching process, ensuring more stable casting quality while enhancing both eco-friendliness and operator safety.

We employ a fully controlled desilication line equipped with temperature regulation, continuous pH monitoring, and automated filtration to maintain solution quality.

Our process has been proven safe and effective for stainless steel grades such as SS304, SS316, and SS316L, consistently achieving clean, inclusion-free surfaces for marine, petrochemical, and precision hardware applications.

Learn more about Waterson’s award-winning investment casting upgrades

Caustic leaching is a vital post-casting process that ensures complete removal of ceramic shell residues while maintaining metal surface integrity.

By controlling temperature, concentration, and time, Waterson achieves a balance of cleanliness, safety, and sustainability, supporting high-precision industries that demand both quality and environmental responsibility.

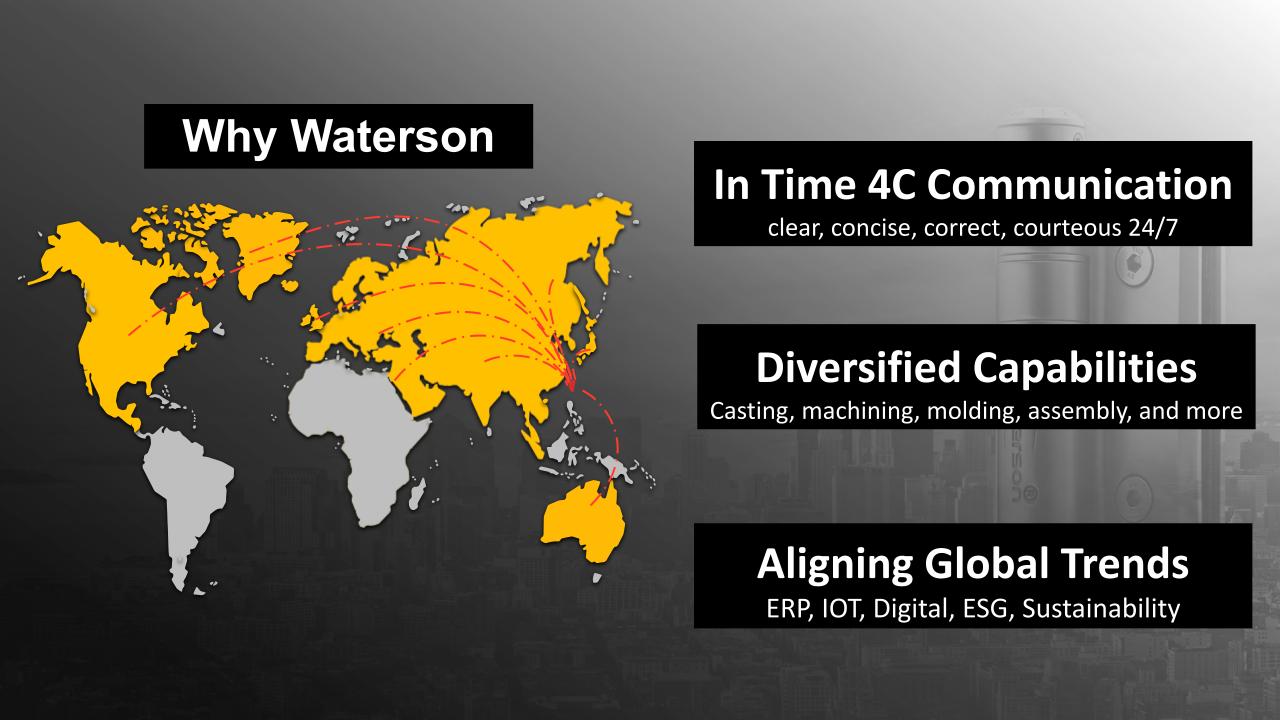

Why Choose Waterson Investment Casting?

At Waterson Corporation, we don’t just offer competitive pricing—we deliver real value. Our expertise in precision investment casting is built on what matters most to today’s global buyers:

- Reliable part performance

- Dimensional accuracy

- Consistent quality

- Regulatory compliance

We understand that in markets like the U.S. and EU, your casting supplier needs to meet more than just cost targets. You need a partner who supports your sustainability goals, provides full traceability, and helps reduce your total cost of ownership through dependable supply and technical support.

If you’re looking for a casting manufacturer that delivers long-term value—not just parts, we’re here to help.

Contact us at info@waterson.com to discuss your next project. Let’s build something better together!

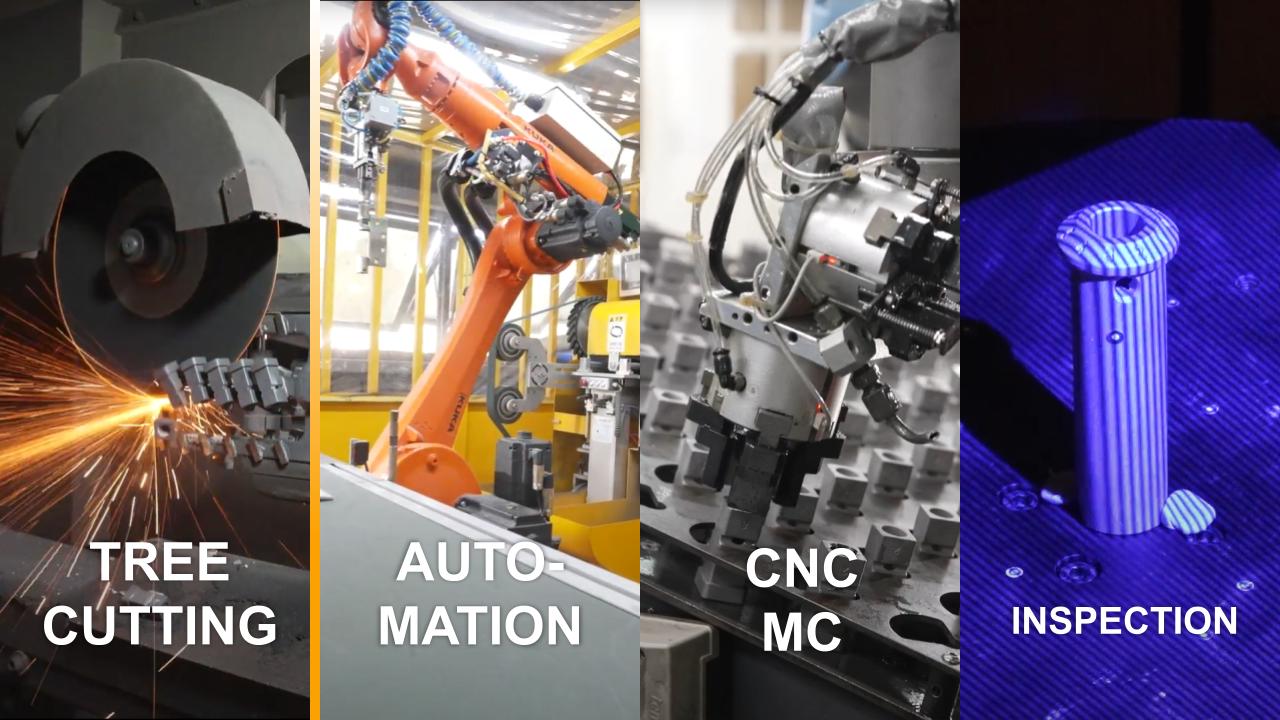

Why Waterson Investment Casting Methods Stand Out

Waterson Corporation is a leading metal products manufacturer specializing in components for the most challenging global applications. Clients benefit from Waterson’s investment casting process, which excel in precision, durability, and surface quality—delivering unmatched reliability and performance across diverse applications.

- Precision Casting: Intricate, robust components for demanding industries.

- Superior Finish: Near-perfect surfaces with minimal processing.

- ISO 2768 Standard: Exceeds aerospace, marine, and petrochemical benchmarks.

- Versatile Materials: Tailored solutions in stainless steel and alloys with efficient material cost.

Waterson Stainless Steel Investment Casting Solutions

Waterson Precision Investment Casting is a wax-based foundry located in Taiwan specializing in stainless steel precision casting. It delivers high-volume, consistently high-quality castings to industries such as door hardware, petrochemicals, medical equipment, marine, hand tools, and food equipment. With an impressive 95% above self-production rate, Waterson’s production line encompasses mold design, fluid analysis, wax model creation, shell making, dewaxing, metal pouring, post-processing (e.g., acid pickling, alkaline treatment), sandblasting, heat treatment, machining, assembly, and packaging. Its stainless steel production line supports materials such as 304 (CF8), 316 (CF8M), and 17-4 stainless steel. Currently, there is available production capacity—feel free to contact info@waterson.com.