Investment casting is essential in industries such as aerospace, automotive, and medical technology. However, as Europe prioritises sustainability, decarbonising this energy-intensive manufacturing process is critical. Clean manufacturing provides a robust path towards significant carbon emission reductions, aligning the industry with the EU’s ambitious environmental targets.

Table of Contents

ToggleWhat is Clean Manufacturing

Clean manufacturing refers to the design and execution of industrial processes that reduce environmental impact across the entire product lifecycle. It focuses on minimizing waste, conserving energy and resources, and reducing harmful emissions, all while maintaining product quality and ensuring economic competitiveness. Additionally, clean manufacturing prioritizes the health and safety of workers, communities, and end-users, aiming for sustainable production practices that support both environmental and social responsibility.

Why is Decarbonization Important in Investment Casting

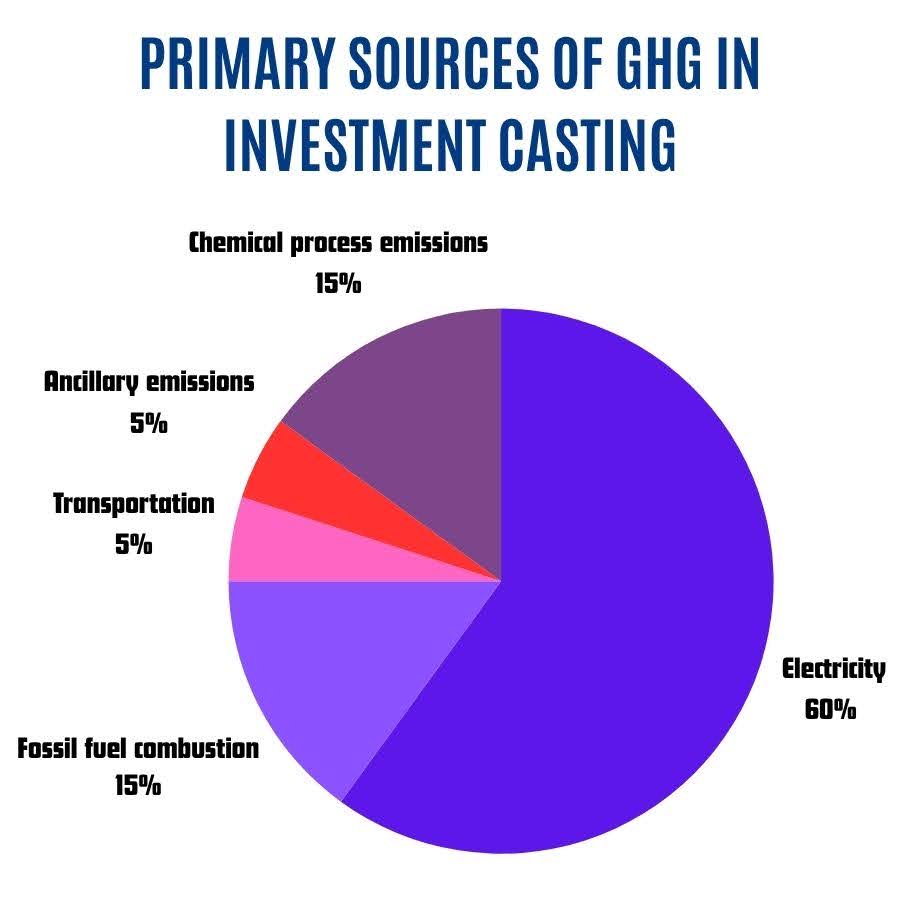

The investment casting industry is notably energy-intensive, contributing substantially to greenhouse gas (GHG) emissions. Major emission sources include:

- Electricity use (approximately 60%)

- Fossil fuel combustion (15%)

- Chemical process emissions (15%)

- Transportation (5%)

- Ancillary emissions (5%)

Reducing these emissions is essential for:

- Meeting stringent EU regulations and UK industry standards

- Maintaining competitiveness

- Attracting sustainability-minded clients

- Ensuring long-term market viability

Discover more about decarbonization strategies for investment casting here.

Embracing Productivity with Clean Manufacturing Strategies

Investment casting foundries can implement clean manufacturing strategies by:

- Transitioning to renewable energy sources, such as integrating heat recovery technology in sintering furnace equipment. This approach captures and reuses waste heat, significantly reducing energy consumption and emissions.

- Improving energy efficiency through advanced technologies such as efficient furnaces and automation systems, thus minimising energy waste.

- Adopting a circular economy, which includes:

-

- Recycling

- Waste minimisation

- Resource conservation

-

These strategies collectively assist foundries in reducing their carbon footprint, ensuring industry compliance, and achieving broader environmental objectives.

Transitioning to renewable energy sources is key, particularly through integrating heat recovery technology in sintering furnace equipment. To further enhance energy efficiency, Waterson Corporation has collaborated with the Taiwanese government through the Metal Processing Equipment Enhancement Plan. Learn more about how Waterson is boosting energy efficiency here.

Leading the Way in Sustainable Investment Casting

Waterson Corporation is proactively advancing towards green manufacturing, embodying the principles of sustainability, precision, and quality by:

- Optimising energy efficiency

- Adopting circular economy practices

Additionally, Waterson Corporation is actively preparing for the Carbon Border Adjustment Mechanism (CBAM), ensuring compliance and readiness for future European market requirements. With these initiatives, Waterson is set to become Europe’s most reliable partner for metal casting parts, delivering quality, precision, and environmental responsibility. Our casting advantages and metal products can show the quality, precision, and environmental responsibility harmoniously intersect.

Why Waterson Investment Casting Methods Stand Out

Waterson Corporation is a leading metal products manufacturer specializing in components for the most challenging global applications. Clients benefit from Waterson’s investment casting process, which excel in precision, durability, and surface quality—delivering unmatched reliability and performance across diverse applications.

- Precision Casting: Intricate, robust components for demanding industries.

- Superior Finish: Near-perfect surfaces with minimal processing.

- ISO 2768 Standard: Exceeds aerospace, marine, and petrochemical benchmarks.

- Versatile Materials: Tailored solutions in stainless steel and alloys.

Waterson Stainless Steel Investment Casting Solutions

Waterson Precision Casting is a wax-based foundry located in Taiwan specializing in stainless steel precision casting. It delivers high-volume, consistently high-quality castings to industries such as door hardware, petrochemicals, medical equipment, marine, hand tools, and food equipment. With an impressive 95% above self-production rate, Waterson’s production line encompasses mold design, fluid analysis, wax model creation, shell making, dewaxing, metal pouring, post-processing (e.g., acid pickling, alkaline treatment), sandblasting, heat treatment, machining, assembly, and packaging. Its stainless steel production line supports materials such as 304 (CF8), 316 (CF8M), and 17-4 stainless steel. Currently, there is available production capacity—feel free to contact info@waterson.com !