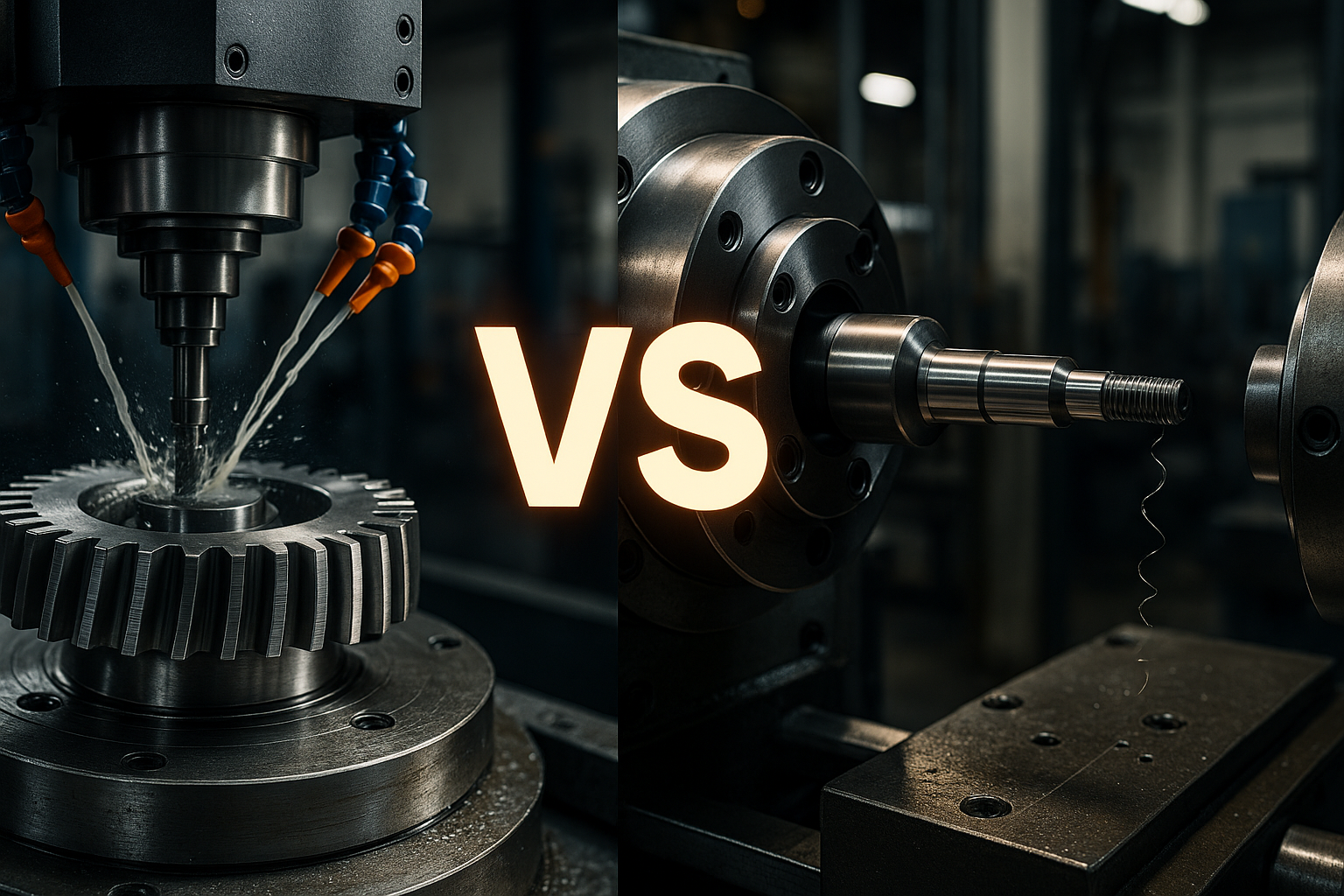

Both CNC machining and screw machining are integral in transforming investment casting or precision casting blanks into high-quality metal components. CNC machining, operated via CAD/CAM systems, excels at producing complex and bespoke geometries with exceptional accuracy. By contrast, screw machining — typically performed on Swiss-type or multi-spindle automatic lathes — is optimised for rapid, high-volume manufacture of small, cylindrical parts.

So, CNC machining vs screw machining — which process is the better fit for your production needs?

Table of Contents

Toggle- Features of CNC Machining

- Features of Screw Machining

- Balancing Casting and Machining: When Each Method Excels

- Combining Investment Casting and Machining for Optimal Results

- Why Choose Waterson Investment Casting?

- Why Waterson Investment Casting Methods Stand Out

- Waterson Stainless Steel Investment Casting Solutions

Features of CNC Machining

- Adaptability and Speed: CNC machining is well-suited for rapid prototyping and low- to medium-volume production, as it often avoids the tooling requirements associated with casting and, in some cases, can machine directly from bar stock, helping to shorten product development time.

- Superior Precision: Modern CNC systems are capable of tolerances as fine as ±0.0025 mm, making them ideal for finishing precision-cast parts to exacting specifications.

- Material and Geometrical Flexibility: CNC accommodates a broad range of metals and alloys and is adept at producing complex, non-symmetrical geometries — a key advantage for post-casting feature refinement.

Features of Screw Machining

- High Throughput and Automation: Screw machines, particularly Swiss-type designs, are engineered for fast, automated production with minimal operator intervention, enabling efficient large-batch output.

- Accuracy for Cylindrical Parts: They deliver excellent precision for rotationally symmetrical shapes, which is advantageous when refining cylindrical cast components.

- Cost-Efficiency at Scale: Although set-up may be more involved, screw machining typically offers lower unit costs for high-volume runs, particularly when starting from bar stock or simple cast blanks.

Need help understanding machining terms? Check out Waterson’s trusted machining glossary!

Balancing Casting and Machining: When Each Method Excels

When working with precision casting or investment casting, the choice between CNC and screw machining generally depends on part complexity, production volume, and lead-time requirements:

- One-off or low-volume, complex parts → CNC Machining: Best suited to intricate features, prototyping, and flexibility without the delays of mould tooling.

- High-volume, symmetrical parts → Screw Machining: Most efficient and cost-effective for repeated production of cylindrical components.

- Post-casting finishing → CNC Machining: Provides the dimensional accuracy and adaptability needed for final finishing and tolerance control.

Combining Investment Casting and Machining for Optimal Results

In many cases, the most efficient production route is to combine investment casting for the initial net-shape with the most appropriate machining method for finishing. CNC machining can achieve complex detailing and critical tolerances, while screw machining can deliver cost-effective throughput for simpler geometries at scale. This integrated approach reduces waste, shortens overall lead times, and ensures each part meets exact specification.

Need a single partner to handle all your casting and machining needs? See Waterson’s benefits and get in touch by mailing to info@waterson.com today!

Why Choose Waterson Investment Casting?

At Waterson Corporation, we don’t just offer competitive pricing—we deliver real value. Our expertise in precision investment casting is built on what matters most to today’s global buyers:

- Reliable part performance

- Dimensional accuracy

- Consistent quality

- Regulatory compliance

We understand that in markets like the U.S. and EU, your casting supplier needs to meet more than just cost targets. You need a partner who supports your sustainability goals, provides full traceability, and helps reduce your total cost of ownership through dependable supply and technical support.

If you’re looking for a casting manufacturer that delivers long-term value—not just parts, we’re here to help.

Contact us at info@waterson.com to discuss your next project. Let’s build something better together!

Why Waterson Investment Casting Methods Stand Out

Waterson Corporation is a leading metal products manufacturer specializing in components for the most challenging global applications. Clients benefit from Waterson’s investment casting process, which excel in precision, durability, and surface quality—delivering unmatched reliability and performance across diverse applications.

- Precision Casting: Intricate, robust components for demanding industries.

- Superior Finish: Near-perfect surfaces with minimal processing.

- ISO 2768 Standard: Exceeds aerospace, marine, and petrochemical benchmarks.

- Versatile Materials: Tailored solutions in stainless steel and alloys with efficient material cost.

Waterson Stainless Steel Investment Casting Solutions

Waterson Precision Investment Casting is a wax-based foundry located in Taiwan specializing in stainless steel precision casting. It delivers high-volume, consistently high-quality castings to industries such as door hardware, petrochemicals, medical equipment, marine, hand tools, and food equipment. With an impressive 95% above self-production rate, Waterson’s production line encompasses mold design, fluid analysis, wax model creation, shell making, dewaxing, metal pouring, post-processing (e.g., acid pickling, alkaline treatment), sandblasting, heat treatment, machining, assembly, and packaging. Its stainless steel production line supports materials such as 304 (CF8), 316 (CF8M), and 17-4 stainless steel. Currently, there is available production capacity—feel free to contact info@waterson.com.