If you’ve ever been surprised by how much a “low-cost” component ended up costing you in the long run, you’re not alone. For many buyers in manufacturing, the quoted price of an investment cast part only tells a small part of the story.

That’s why understanding the Total Cost of Ownership (TCO) is no longer optional. It’s a necessity for anyone managing procurement, engineering, or supplier performance. It’s not just about how much you pay per piece. It’s about everything that happens after you receive that part.

Table of Contents

Toggle- But, What is Total Cost of Ownership (TCO)?

- The Quoted Price Is Just the Beginning

- When Quality Fails, the Casting Costs Multiply

- Logistics: The Hidden Layer of Investment Casting Cost

- Compliance, Sustainability, and Reputation

- So, What Does This Mean for You?

- Why Choose Waterson Investment Casting?

- Why Waterson Investment Casting Methods Stand Out

- Waterson Stainless Steel Investment Casting Solutions

But, What is Total Cost of Ownership (TCO)?

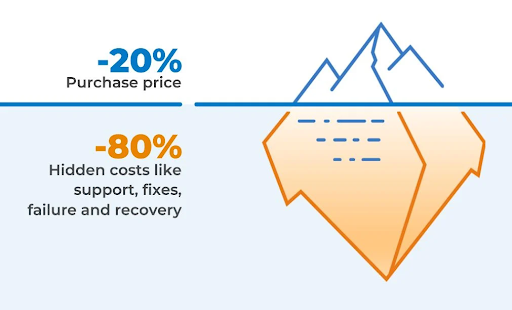

Total Cost of Ownership (TCO) refers to the full cost involved in owning an asset over its entire lifecycle—not just the initial purchase. It reflects both direct and indirect expenses tied to acquisition, daily operations, maintenance, support, and final disposal. All of these TCO factors can help businesses make smarter investment decisions by considering long-term value and hidden costs, not just the upfront price.

The Quoted Price Is Just the Beginning

Yes, the unit price matters, especially when you’re managing a tight budget. But here’s the reality: a $12 part from one supplier might cost you less over time than a $9 part from another.

So, how much does casting cost? While the unit price might seem like the most important number, it rarely reflects the true cost.

Here’s what often gets left out:

- Machining allowances

Poorly cast parts may require extra machining, increasing time and labor costs. - Surface finish quality

A smoother finish reduces the need for grinding or polishing, saving downstream effort. - Dimensional consistency

Parts that vary in size create assembly issues and increase inspection time. - Packaging and handling

Properly protected parts reduce damage and rework during transport and storage.

A part that arrives truly “ready to use” may cost a few dollars more upfront, but over time, it helps avoid far greater expenses in labor, equipment wear, and delays.

When Quality Fails, the Casting Costs Multiply

A metal casting defect doesn’t just affect one piece. It slows down processes, creates bottlenecks, and disrupts the flow of production.

Poor quality can lead to:

- Internal failures and rework

Recasting or re-machining takes up floor space and technician hours. - Inspection and sorting

Additional quality control checks drain resources and increase lead time. - External returns or warranty issues

Product failures in the field damage your brand and cost money to fix. - Missed deadlines and customer dissatisfaction

Late deliveries can result in lost contracts or penalties.

According to ASQ, quality-related costs can account for 15–40% of total manufacturing expenses when not proactively addressed. That’s why choosing a supplier with robust quality systems, documented traceability, and reliable manufacturing process control is not just a preference—it’s a risk mitigation and cost-effective strategy.

Logistics: The Hidden Layer of Investment Casting Cost

Many buyers overlook the impact of logistics, even though it can reshape the economics of a project.

Key logistical cost drivers include:

- Shipping delays

A stalled shipment can halt entire production lines and force last-minute adjustments. - Customs and regulatory clearance

Unexpected fees or documentation issues can add weeks to delivery schedules. - Inventory holding costs

Longer lead times require larger safety stock, tying up capital and warehouse space.

In today’s global environment, unpredictable logistics have become a business reality. If your supplier can’t deliver on time, your production takes the hit.

Compliance, Sustainability, and Reputation

Today’s buyers are expected to go beyond the investment casting cost—they must ensure compliance, transparency, and environmental responsibility.

Risks you may not be seeing include:

- Non-compliance with CBAM, RoHS, or REACH

Regulatory failure can make parts unusable or trigger penalties. - Lack of documentation

Missing test reports, certificates, or material data sheets create delays in audits or approvals. - Sustainability concerns

Suppliers that don’t meet ESG expectations can disqualify you from contracts, especially in EU markets.

In other words, the wrong supplier may cost you not just money, but also credibility and long-term customer trust.

So, What Does This Mean for You?

Choosing the right casting partner isn’t about chasing the lowest quote. It’s about evaluating the full impact of each sourcing decision.

The best sourcing decisions consider the full picture:

- Production readiness and integration

- Quality control and post-sale reliability

- Lead times and delivery consistency

- Environmental and regulatory alignment

This is the essence of Total Cost of Ownership. It’s a mindset that separates reactive buyers from strategic ones—and it’s what protects your margins, your timelines, and your reputation.

Why Choose Waterson Investment Casting?

At Waterson Corporation, we don’t just offer competitive pricing—we deliver real value. Our expertise in precision investment casting is built on what matters most to today’s global buyers:

- Reliable part performance

- Dimensional accuracy

- Consistent quality

- Regulatory compliance

We understand that in markets like the U.S. and EU, your casting supplier needs to meet more than just cost targets. You need a partner who supports your sustainability goals, provides full traceability, and helps reduce your total cost of ownership through dependable supply and technical support.

If you’re looking for a casting manufacturer that delivers long-term value—not just parts, we’re here to help.

Contact us at info@waterson.com to discuss your next project. Let’s build something better together!

Why Waterson Investment Casting Methods Stand Out

Waterson Corporation is a leading metal products manufacturer specializing in components for the most challenging global applications. Clients benefit from Waterson’s investment casting process, which excel in precision, durability, and surface quality—delivering unmatched reliability and performance across diverse applications.

- Precision Casting: Intricate, robust components for demanding industries.

- Superior Finish: Near-perfect surfaces with minimal processing.

- ISO 2768 Standard: Exceeds aerospace, marine, and petrochemical benchmarks.

- Versatile Materials: Tailored solutions in stainless steel and alloys with efficient material cost.

Waterson Stainless Steel Investment Casting Solutions

Waterson Precision Investment Casting is a wax-based foundry located in Taiwan specializing in stainless steel precision casting. It delivers high-volume, consistently high-quality castings to industries such as door hardware, petrochemicals, medical equipment, marine, hand tools, and food equipment. With an impressive 95% above self-production rate, Waterson’s production line encompasses mold design, fluid analysis, wax model creation, shell making, dewaxing, metal pouring, post-processing (e.g., acid pickling, alkaline treatment), sandblasting, heat treatment, machining, assembly, and packaging. Its stainless steel production line supports materials such as 304 (CF8), 316 (CF8M), and 17-4 stainless steel. Currently, there is available production capacity—feel free to contact info@waterson.com.