Is your business scaling faster than your current manufacturing processes can handle? If you’re finding that traditional metal machining just can’t keep up, you’re not alone. Many companies hit a critical point where they need faster, more efficient production—without sacrificing quality. That’s where investment casting steps in as a next-level solution.

Table of Contents

ToggleWhen Is It Time to Switch to Investment Casting?

1. Production Volume Has Outgrown Machining

If you’re facing bottlenecks and missed deadlines due to limited machining capacity, it’s time to consider a scalable alternative. Investment casting is ideal when:

-

-

- You need to produce at least thousands of parts per month

- Demand has doubled or tripled in a short time

- Machining lead times are too long to stay competitive

- You need to increase output without compromising precision

-

2. Real-World Example

One of our fast-growing clients shared:

“Our sales have exploded, but our machining can’t keep up. We’re now looking to produce 10,000 precision parts monthly, so we’re shifting to investment casting to scale up efficiently.”

This shift allowed the client to meet demand without inflating costs or extending delivery timelines.

How to Prepare for a Smooth Investment Casting Quote

Transitioning to investment casting requires upfront planning. To get an accurate and timely quote from an investment casting foundry, make sure to include:

1. Must-Have Documentation

- 2D Technical Drawings – Include all dimensions and tolerances

- 3D CAD Models (STEP format preferred) – Enables rapid mold design

- Material Specifications – Define mechanical and chemical properties

- Expected Monthly Production Volumes – Helps assess tooling and casting method

- Target Delivery Timelines – Critical for planning production ramp-up

Design Adjustments for Investment Casting Success

Investment casting offers complex geometries and tight tolerances—but designs originally created for machining may require some tweaks:

- Add Machining or Surface Treatment Allowances – Leave extra material for CNC or other special finishing where tight tolerances are critical

- Include Draft Angles – Aids in wax pattern removal during mold making

- Optimize Wall Thickness – Uniform thickness ensures smooth metal flow

- Smooth Out Sharp Corners – Use radii and fillets to improve castability and reduce defects

Ready to Scale Your Manufacturing with Investment Casting?

Whether you’re manufacturing aerospace components, firearm parts, marine hardware, medical instruments, petrochemical fittings, or automotive precision parts, investment casting delivers the precision, consistency, and scalability your industry demands. It’s the ideal solution for complex geometries, tight tolerances, and high-volume production.

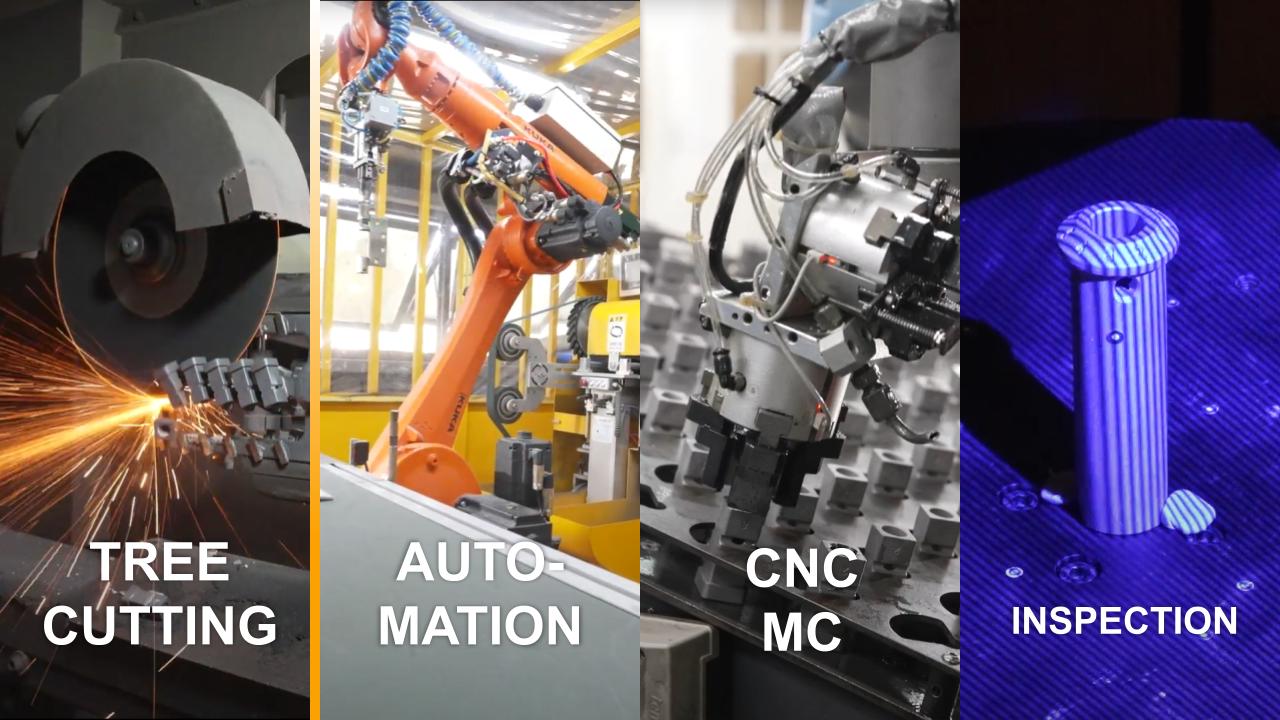

Why Waterson Investment Casting Methods Stand Out

Waterson Corporation is a leading metal products manufacturer specializing in components for the most challenging global applications. Clients benefit from Waterson’s investment casting process, which excel in precision, durability, and surface quality—delivering unmatched reliability and performance across diverse applications.

- Precision Casting: Intricate, robust components for demanding industries.

- Superior Finish: Near-perfect surfaces with minimal processing.

- ISO 2768 Standard: Exceeds aerospace, marine, and petrochemical benchmarks.

- Versatile Materials: Tailored solutions in stainless steel and alloys.

Waterson Stainless Steel Investment Casting Solutions

Waterson Precision Casting is a wax-based foundry located in Taiwan (near China) specializing in stainless steel precision casting. It delivers high-volume, consistently high-quality castings to industries such as door hardware, petrochemicals, medical equipment, marine, hand tools, and food equipment. With an impressive 95% above self-production rate, Waterson’s production line encompasses mold design, fluid analysis, wax model creation, shell making, dewaxing, metal pouring, post-processing (e.g., acid pickling, alkaline treatment), sandblasting, heat treatment, machining, assembly, and packaging. Its stainless steel production line supports materials such as 304 (CF8), 316 (CF8M), and 17-4 stainless steel. Currently, there is available production capacity—feel free to request a quote!