In modern investment casting, there’s no room for guesswork. Advanced foundries across Europe and Australia are adopting simulation tools to refine their production workflows, cut down development time, and consistently deliver high-precision components. These digital tools have become vital in ensuring accuracy and reliability throughout the lost wax casting process.

Table of Contents

Toggle- Understanding the Challenge of Precision Investment Casting

- The Shift from Physical Trials to Digital Simulation

- Simulation Investment Casting’s Key Areas Enhances

- Why Simulation Matters for Modern Foundries

- Backed by 40 Years of Casting Expertise at Waterson

- How Outstanding Are Waterson Investment Casting Methods

- Waterson Stainless Steel Investment Casting Solutions

Understanding the Challenge of Precision Investment Casting

The precision investment casting technique relies heavily on exact control of how molten metal behaves inside the mould—from initial flow to final cooling. Any inconsistency can lead to defects such as misruns, internal cavities, or warping. Traditionally, engineers depended on manual adjustments and physical trials to troubleshoot issues, an approach that was both time-consuming and inefficient.

With today’s demand for tighter tolerances and faster lead times, relying solely on physical iterations is no longer viable. That’s where investment casting simulation comes in.

The Shift from Physical Trials to Digital Simulation

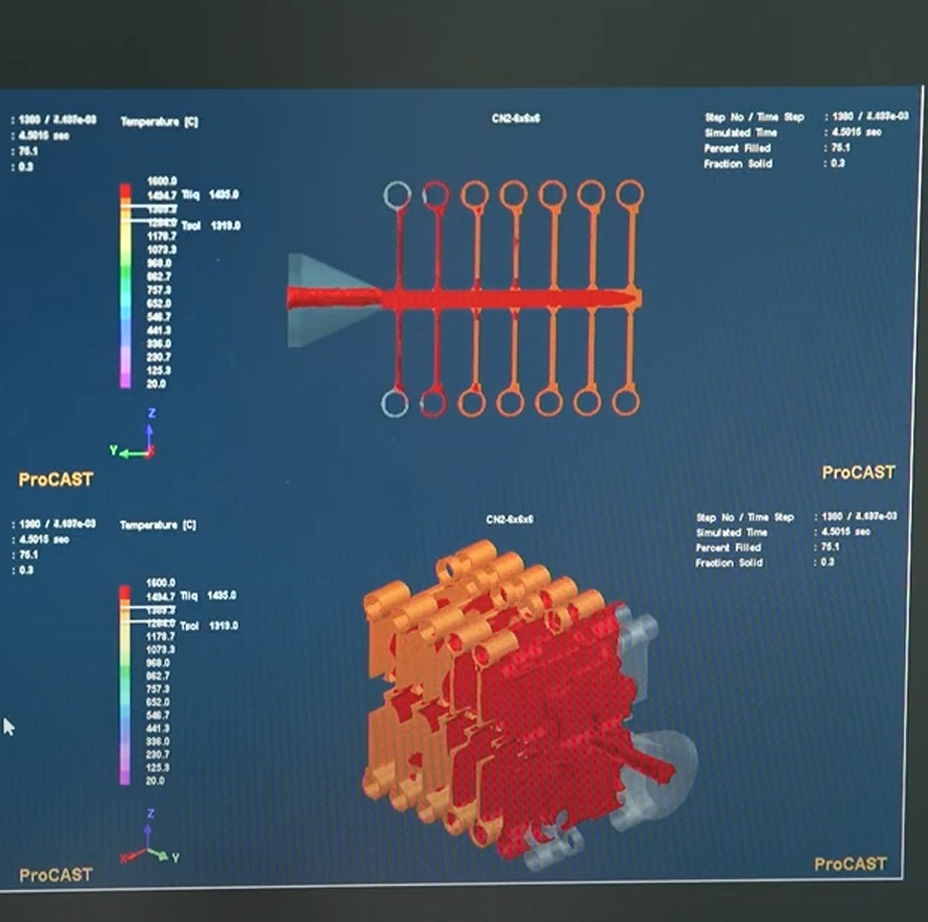

Simulation software, such as mould flow analysis, allows engineers to create a digital twin of the entire lost wax casting sequence. This includes:

- Analysing molten metal behaviour during cavity filling

- Predicting temperature gradients through the ceramic shell

- Simulating wax injection for accurate pattern replication

- Optimising sprue layouts to maximise yield and minimise turbulence

By forecasting potential flaws before any actual metal is poured, investment casting simulation drastically reduces the number of physical trials required, cutting development cycles and improving first-shot success rates.

Explore Waterson’s full range of investment casting capabilities.

Simulation Investment Casting’s Key Areas Enhances

Wax Pattern Accuracy

Digital moulding simulations ensure wax fully occupies the mould cavity, compensating for shrinkage and avoiding surface irregularities that could compromise the finished product.

Ceramic Shell Performance

Modelling how ceramic layers build up around the wax form helps determine ideal thickness for both thermal resistance and mechanical integrity. This directly influences how metal solidifies inside the mould.

Metal Flow and Cooling Control

Through mould flow analysis, engineers can adjust runner and gating designs to ensure metal enters the mould steadily, avoiding splashing or air entrapment. Thermal simulation further helps predict where hotspots or premature solidification might occur, guiding refinements in shell design or pouring speed.

Why Simulation Matters for Modern Foundries

Virtual testing offers significant benefits for precision investment casting operations, including:

- Fewer production errors and rework

- Greater consistency in mechanical properties

- More efficient use of materials and energy

- Increased output with lower scrap rates

- Improved capacity for casting complex or safety-critical components

Ultimately, simulation transforms investment casting from a reactive to a proactive process, helping manufacturers deliver consistently high-quality results while keeping costs and timelines under control.

Backed by 40 Years of Casting Expertise at Waterson

With over four decades of experience in precision investment casting, Waterson Corporation has built a reputation for engineering excellence, consistent quality, and responsive service. Our strength lies not only in advanced tools like mould flow analysis, but in our ability to manage the entire lost wax casting process—from in-house toolmaking and wax injection to ceramic shell building, metal pouring, and precision machining.

Waterson’s vertically integrated operations ensure tight control over every stage of production, allowing us to maintain stringent quality standards and reduce lead times. Whether you’re sourcing complex components for marine, petrochemical, or industrial applications, our team is equipped to deliver cost-effective, high-performance results you can rely on.

Waterson Corporation collaborates with trusted partners to offer these capabilities. Learn more about our capabilities.

How Outstanding Are Waterson Investment Casting Methods

Waterson Corporation is a leading metal products manufacturer specializing in components for the most challenging global applications. Clients benefit from Waterson’s investment casting process, which excel in precision, durability, and surface quality—delivering unmatched reliability and performance across diverse applications.

- Precision Casting: Intricate, robust components for demanding industries.

- Superior Finish: Near-perfect surfaces with minimal processing

- ISO 2768 Standard: Exceeds aerospace, marine, and petrochemical benchmarks.

- Versatile Materials: Tailored solutions in stainless steel and alloys with efficient material cost.

Waterson Stainless Steel Investment Casting Solutions

Waterson Precision Investment Casting is a wax-based foundry located in Taiwan specializing in stainless steel precision casting. It delivers high-volume, consistently high-quality castings to industries such as door hardware, petrochemicals, medical equipment, marine, hand tools, and food equipment. With an impressive 95% above self-production rate, Waterson’s production line encompasses mold design, fluid analysis, wax model creation, shell making, dewaxing, metal pouring, post-processing (e.g., acid pickling, alkaline treatment), sandblasting, heat treatment, machining, assembly, and packaging. Its stainless steel production line supports materials such as 304 (CF8), 316 (CF8M), and 17-4 stainless steel. Currently, there is available production capacity—feel free to contact info@waterson.com.