When producing investment casting surface finishes, especially in stainless steel, buyers often want to know what level of smoothness, reflectivity, or texture can be achieved. Surface finishing is not only about appearance – it directly affects performance, corrosion resistance, and suitability for industries such as marine hardware, petrochemicals, and architectural applications.

Table of Contents

Toggle- Why Surface Finish Matters

- Understanding Ra, Grit and Finish Numbers

- Common Stainless Steel Finishes in Investment Casting

- Matching Surface Finish to Multiple Application

- Making the Best Choice for Your Stainless Steel Casting

- Partner with an Experienced Surface Finish Expert

- Why Choose Waterson Investment Casting?

- Why Waterson Investment Casting Methods Stand Out

- Waterson Stainless Steel Investment Casting Solutions

Why Surface Finish Matters

The surface finish of investment castings depends on several factors:

- The type of stainless steel alloy used

- The finishing method, such as bead blasting, polishing, or electropolishing

- Equipment and abrasives applied during the process

- The level of skill or automation involved

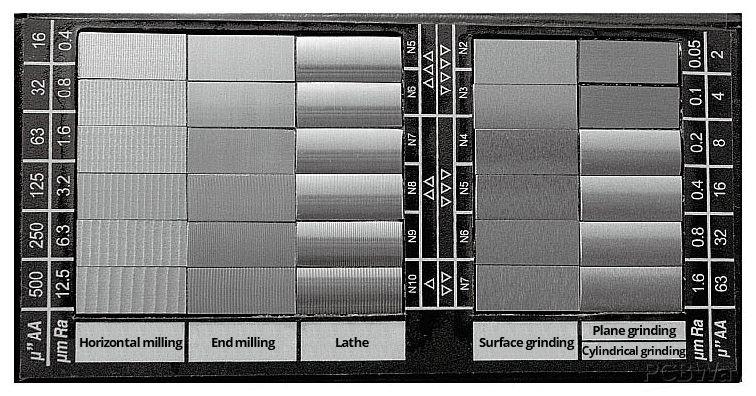

For many buyers, Ra value (roughness average) is the most reliable way to compare surface finishes. Roughness average (Ra) is the most accurate and is measured in microinches. Grit and polish numbers, on the other hand, depend on the methods and materials used and are more of a subjective assessment. This makes Ra a clear benchmark, especially when specifying requirements for precision components.

Discover how Waterson’s advanced surface treatment expertise helps you achieve the perfect finish.

Understanding Ra, Grit and Finish Numbers

When specifying an investment casting surface finish, three terms often appear together: Ra value (roughness average), grit size, and the industry’s finish number.

- Ra (roughness average) is the most precise way to measure surface smoothness. It is expressed in microinches: the lower the Ra, the smoother the surface.

- Grit size refers to the abrasives used during polishing. A higher grit number means finer abrasives, which create a smoother finish.

- Finish numbers (No. 3, 4, 7, 8 etc.) are industry shorthand for different surface appearances, ranging from dull matte to mirror polish.

Common Stainless Steel Finishes in Investment Casting

Mill & Unpolished Finishes

- No. 1 Finish – Dull and matte, produced by hot rolling, annealing, and descaling.

- No. 2D Finish – Similar to No. 1 but cold-rolled, also dull in appearance.

- No. 2B Finish – Brighter than No. 2D, easier to polish further, widely used as a general-purpose finish.

Polished & Buffed Finishes

- No. 3 Finish – Semi-polished with medium abrasives, suitable for parts that will undergo further processing.

- No. 4 Finish – A widely used bright polished surface, ideal for kitchen equipment, dairy parts, and decorative fittings.

- No. 6 Finish – A satin-like texture, softer in appearance than No. 4.

- No. 7 Finish – Highly reflective, created through additional buffing after a No. 6 base.

- No. 8 Finish – The highest level of polish, often called a “mirror finish”, used in decorative or high-end architectural pieces.

| Ra (µin) | Grit | Finish No. |

| 43-48 | 120 | 3 |

| 30-35 | 150 | 4 |

| 23-28 | 180 | 4 |

| 15-20 | 240 | 7 |

| 9-17 | 320 | 8 |

| 4-16 | 400 | 8 |

Matching Surface Finish to Multiple Application

- Marine hardware: Often requires shot blasting or electropolishing to enhance corrosion resistance and durability in saltwater environments.

- Petrochemical equipment: Smooth Ra values with passivation help resist chemical attack and ensure safety compliance.

- Decorative or architectural products: Mirror-polished No. 8 surfaces are preferred for their reflective appearance.

- Industrial components: A functional Ra finish (often from bead blasting or No. 4 polish) balances cost, performance, and appearance.

Making the Best Choice for Your Stainless Steel Casting

When sourcing stainless steel castings, understanding investment casting surface finish standards helps ensure you get the right balance of cost, quality, and performance. Whether you need a functional roughness for industrial parts or a high-shine mirror polish for decorative fittings, clear specifications on surface finish Ra values and methods will help manufacturers deliver consistent and reliable results.

Partner with an Experienced Surface Finish Expert

Choosing the right investment casting surface finish can be challenging, but Waterson Corporation makes it simple. With over 40 years of expertise in precision and lost-wax casting, we help buyers in the marine, petrochemical, and architectural sectors select finishes that balance cost, durability, and appearance.

At Waterson, we do more than supply castings; we act as a trusted partner, helping buyers navigate finish standards, assess durability, and achieve the best balance between cost-efficiency and product excellence. Whether you need a robust industrial component or a flawless mirror-polished surface, our total metal solution approach ensures every casting is delivered to the highest international standards.

Why Choose Waterson Investment Casting?

At Waterson Corporation, we don’t just offer competitive pricing—we deliver real value. Our expertise in precision investment casting is built on what matters most to today’s global buyers:

- Reliable part performance

- Dimensional accuracy

- Consistent quality

- Regulatory compliance

We understand that in markets like the U.S. and EU, your casting supplier needs to meet more than just cost targets. You need a partner who supports your sustainability goals, provides full traceability, and helps reduce your total cost of ownership through dependable supply and technical support.

If you’re looking for a casting manufacturer that delivers long-term value—not just parts, we’re here to help.

Contact us at info@waterson.com to discuss your next project. Let’s build something better together!

Why Waterson Investment Casting Methods Stand Out

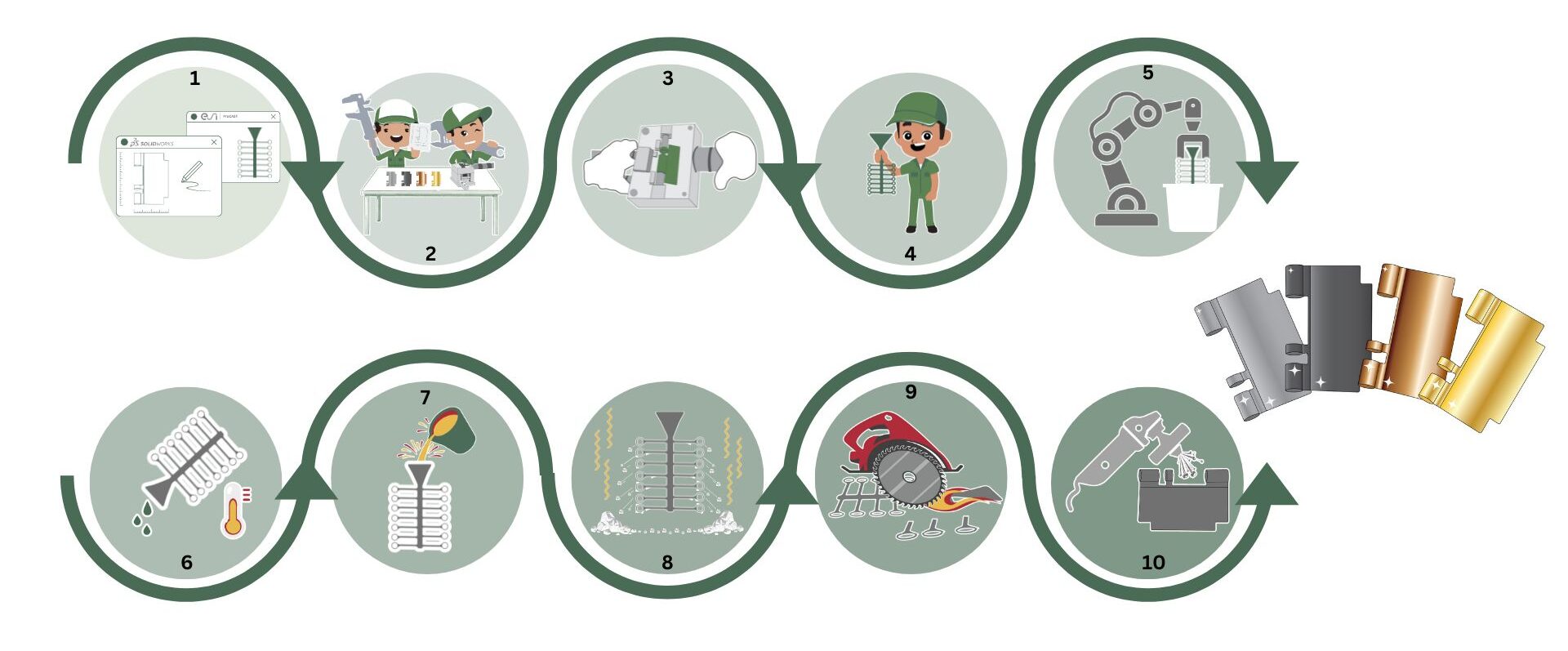

Waterson Corporation is a leading metal products manufacturer specializing in components for the most challenging global applications. Clients benefit from Waterson’s investment casting process, which excel in precision, durability, and surface quality—delivering unmatched reliability and performance across diverse applications.

- Precision Casting: Intricate, robust components for demanding industries.

- Superior Finish: Near-perfect surfaces with minimal processing.

- ISO 2768 Standard: Exceeds aerospace, marine, and petrochemical benchmarks.

- Versatile Materials: Tailored solutions in stainless steel and alloys with efficient material cost.

Waterson Stainless Steel Investment Casting Solutions

Waterson Precision Investment Casting is a wax-based foundry located in Taiwan specializing in stainless steel precision casting. It delivers high-volume, consistently high-quality castings to industries such as door hardware, petrochemicals, medical equipment, marine, hand tools, and food equipment. With an impressive 95% above self-production rate, Waterson’s production line encompasses mold design, fluid analysis, wax model creation, shell making, dewaxing, metal pouring, post-processing (e.g., acid pickling, alkaline treatment), sandblasting, heat treatment, machining, assembly, and packaging. Its stainless steel production line supports materials such as 304 (CF8), 316 (CF8M), and 17-4 stainless steel. Currently, there is available production capacity—feel free to contact info@waterson.com.